Supplier Management System

Online Supplier Management Software

Online Induction >> Supplier Management System

Published 24/08/2025

What is a supplier management system and why do you need one?

A best practice supplier management system ensures that new and existing suppliers and contracting companies go through an extensive end to end management process covering their initial engagement and induction as a supplier through to ongoing performance and compliance review.

Supplier may include contractors and subcontractors through to sole traders.

A best practice supplier management system ensures that new and existing suppliers and contracting companies go through an extensive end to end management process covering their initial engagement and induction as a supplier through to ongoing performance and compliance review.

Supplier may include contractors and subcontractors through to sole traders.

A supplier management workflow first begins with an extensive supplier prequalification, supplier accreditation and approval process to review the safety and risk history of the supplier followed by induction of their staff, a registry of their staff, performance and risk ratings, contacts, work to be carried out, work order history, contracts, project documentation, safety reviews and supplier communications (What is supplier management, 2026).

Some of the areas you might manage in a supplier management system

Supplier Performance Management | Decision Making | Licenses | Setup Tips | Effective Supplier Management | Vendor Management System | Supplier Onboarding System

Supplier Performance Management | Decision Making | Licenses | Setup Tips | Effective Supplier Management | Vendor Management System | Supplier Onboarding System

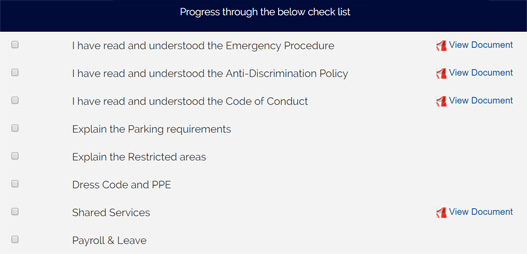

Accreditation as a supplier

The first stage is registration and accreditation of the supplier on a range of areas ranging from their provision of service, safety and performance history, financial capability, experience, insurance and evidence of training and certifications.This workflow involves new suppliers registering online and progressing through a supplier prequalification accreditation form where they will go through an extensive supplier questionnaire. This might be for a sole trader or a representative of a supplier company. Once submitted, the supplier accreditation is submitted and awaits approval. There might be a number of areas to clarify or further upload such as evidence of policies, procedures and systems in place or correct copies of insurances and certifications.

Typically, the supplier accreditation questionnaire might include:

- company registration details

- services to provide

- registered business address

- preferred contacts

- accounts details

- safety history

- providing insurances

- service history - relevent experience

- providing certifications and evidence of qualifications and evidence of training

- how to lodge invoices and company level induction

One of the most critical elements of the supplier accreditation is the risk review, safety performance history due diligence and compliance checks of suppliers. To ensure suppliers are insured and that these insurances are valid and hold the correct type of insurance.

Supplier Prequalification

A part of the accreditation process, suppliers go through an extensive prequalification. The supplier prequalification is basically a due diligence on the suppliers safety, risk and compliance history. This process will typically be an evidence based process where the supplier uploads evidence of their own safety systems, processes and procedures as well as evidence of safety history.For example, prequalification questions might be:

- Does your company have documented procedures for completion of High Risk Work:

- Does your company have documented procedures for safe manual handling:

- Does your company conduct regular internal audits of its own operations:

- Do you undertake safety induction training for your employees and subcontractors:

- In the last 5 years have you been convicted of a WHS breach or been issued with a breach notice by a WHS regulator:

- In the last 5 years have you been convicted of an environmental breach or been issued with a breach notice by the state regulator:

As part of the supplier prequalification process it's important to fully verify and authenticate all performance, compliance and safety information.

Approving the wrong supplier based on the wrong merits could have serious consequences for your organisation.

Make sure that:

Support details confirmed

Support details confirmed Service history reviewed

Service history reviewed  Safety performance is known

Safety performance is known  Quality history has been reviewed

Quality history has been reviewed  Staff performance evaluated

Staff performance evaluated  Insurance details have been verified

Insurance details have been verified Safety history has been reviewed

Safety history has been reviewed  Payment details collected and confirmed

Payment details collected and confirmed  Authorised contacts known and approved

Authorised contacts known and approvedCreate Supplier Management Workflow Journeys

One of the best ways to manage suppliers is with custom workflow journeys. Truly wow your suppliers with the ultimate engagement workflows, nudges and create custom workflow journeys for them to go through. Ranging from notifications, milestones and nudges based on certain activities and actions achieved through to prompts that ensure the supplier is prepared for their job activity in the workplace and even gathering their feedback. Here's an example right here:

Induct all staff from a supplier

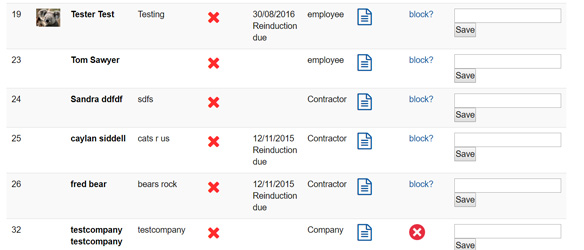

All individual staff who work for a supplier that your organisation has engaged should be inducted into your organisation. From the supplier dashboard, you can then see the status of all your staff and their induction status as well as any training they have provided, renewal dates and manage their ongoing compliance.Setup a Supplier Management Portal

With your own supplier management system portal, you can setup and manage your own custom supplier management workflows easily and efficiently. No two organisations are the same and so its critical ensure your supplier management system can suit your organisations specific workflows and requirements.Supplier Management of Performance

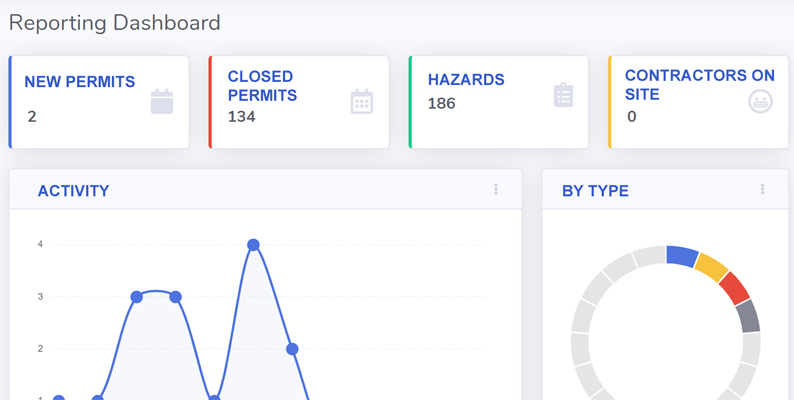

Performance review and ongoing evaluation of the supplier is a major element of supplier management once they have been engaged and start performing tasks for your organisation.

Using deep intelligence gathering technologies such as our modern supplier management software, you can discover, identify and classify all aspects and concern areas around the performance of suppliers.

Performance review and ongoing evaluation of the supplier is a major element of supplier management once they have been engaged and start performing tasks for your organisation.

Using deep intelligence gathering technologies such as our modern supplier management software, you can discover, identify and classify all aspects and concern areas around the performance of suppliers.

New suppliers go to the link and self register

New suppliers go to the link and self register You get a notification when the registration has been successful and is awaiting approval

You get a notification when the registration has been successful and is awaiting approval  Easily manage pending approvals

Easily manage pending approvals Final registry of compliant suppliers and contractors

Final registry of compliant suppliers and contractorsManage work orders, purchase orders and other supplier management options

Once all your suppliers are using a supplier management portal, you can link in uploading purchase orders, invoices, communications, notifications, training and even work requests into a centralised supplier accreditation area.It can be split up into a supplier request form, prequalification process and then supplier management tools as part of their ongoing business and ongoing compliance. See how our supplier accreditation system can work for your organisations needs by looking at the online demo

Supplier Risk Ratings and risk Profile

On an ongoing basic, suppliers should be rated on their level of risk in relation to their work being conducted and their performance as a supplier and their subcontractors. Rate their risk level, categorise them as a company and their individual staff by high, medium and low.- manage suppliers by risk rating

- make data informed decisions about your suppliers based on their performance and metrics around their safety and training history as well as provision of service